Cleanrooms play a crucial role in industries that require strict control over environmental conditions, such as pharmaceuticals, biotechnology, electronics, and healthcare. Maintaining cleanroom operations and ensuring high air quality is of utmost importance. Laminar flow systems have emerged as a reliable solution in Malaysia and worldwide, providing controlled and contaminant-free environments. In this article, we will explore the benefits, implementation, and working principles of laminar flow systems, shedding light on how they contribute to enhanced cleanroom operations and air quality in Malaysia with mylab-plus.

What are Laminar Flow Systems?

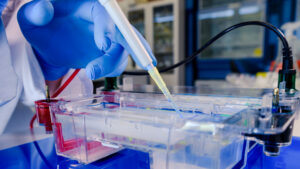

Laminar flow systems are designed to deliver filtered air in a unidirectional and controlled manner within a cleanroom. They employ High Efficiency Particulate Air (HEPA) filters to remove airborne contaminants, ensuring a virtually particle-free environment. Laminar flow systems create a continuous and consistent flow of clean air, minimizing the risk of contamination and maintaining the desired air quality levels.

How do Laminar Flow Systems Work?

Laminar flow systems operate based on the principle of laminar airflow, where air moves in a uniform direction and at a constant velocity. There are two primary types of laminar flow systems: horizontal and vertical.

- Horizontal Laminar Flow Systems: In this configuration, the filtered air is blown in a horizontal direction parallel to the work surface. This setup is commonly used in clean benches and laminar flow hoods, providing a clean workspace for delicate procedures.

- Vertical Laminar Flow Systems: These systems direct the filtered air vertically from the ceiling to the floor, creating a downward airflow. Vertical laminar flow systems are frequently utilized in cleanrooms, where the clean air is supplied to the working area, protecting products and processes from contamination.

The Advantages of Laminar Flow Systems

- Contamination Control: Laminar flow systems ensure a controlled environment by removing particulates, microorganisms, and other contaminants from the air. This is especially crucial in industries where even the tiniest particle can compromise product quality or jeopardize research outcomes.

- Enhanced Productivity: By maintaining a clean and sterile environment, laminar flow systems reduce the risk of product spoilage and contamination-related delays. This improves operational efficiency, leading to higher productivity and reduced costs.

- Personnel Safety: Laminar flow systems provide a protective barrier between operators and potentially hazardous substances, such as toxic chemicals or pathogens. This helps safeguard the health and well-being of personnel working in cleanroom environments.

- Airborne Infection Control: In healthcare facilities and laboratories, laminar flow systems minimize the spread of airborne infections by creating a sterile environment. This is particularly crucial in critical care units and operating theaters where patient safety is of utmost importance.

Conclusion

Laminar flow systems have become an indispensable component of cleanroom operations, ensuring optimal air quality and contamination control in Malaysia’s industrial landscape. By implementing these systems, businesses can enhance productivity, maintain strict regulatory compliance, and safeguard the integrity of their processes and products. Laminar flow technology continues to evolve, offering innovative solutions to meet the ever-increasing demands for cleanroom operations. With their significant advantages and effectiveness, laminar flow systems are a vital investment for any industry that requires a controlled and sterile environment. Embracing this technology will undoubtedly contribute to the growth and success of Malaysia’s cleanroom-dependent industries.